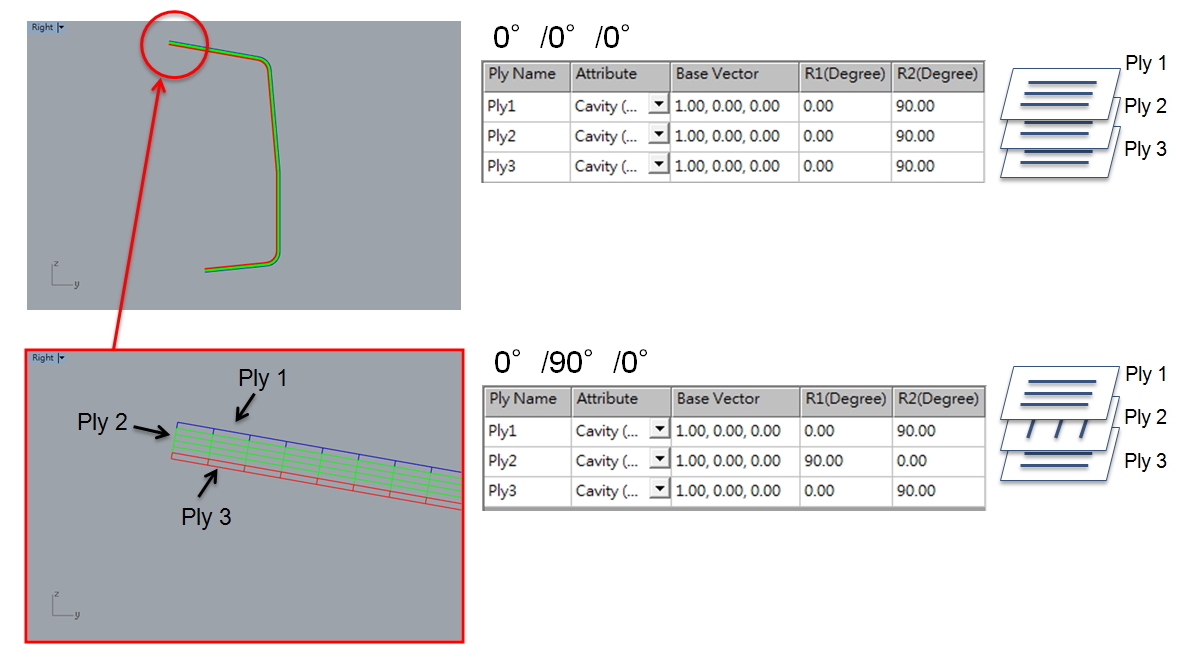

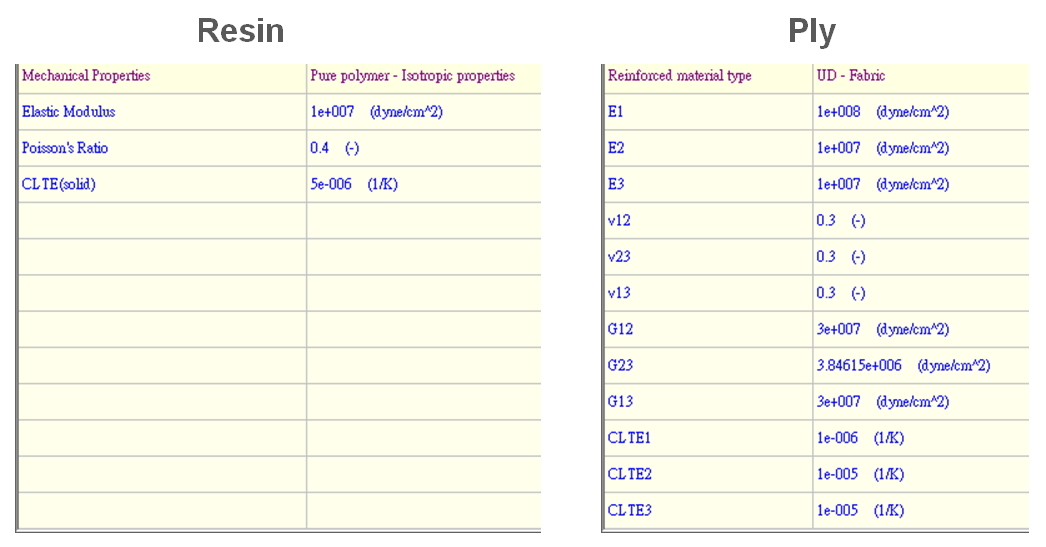

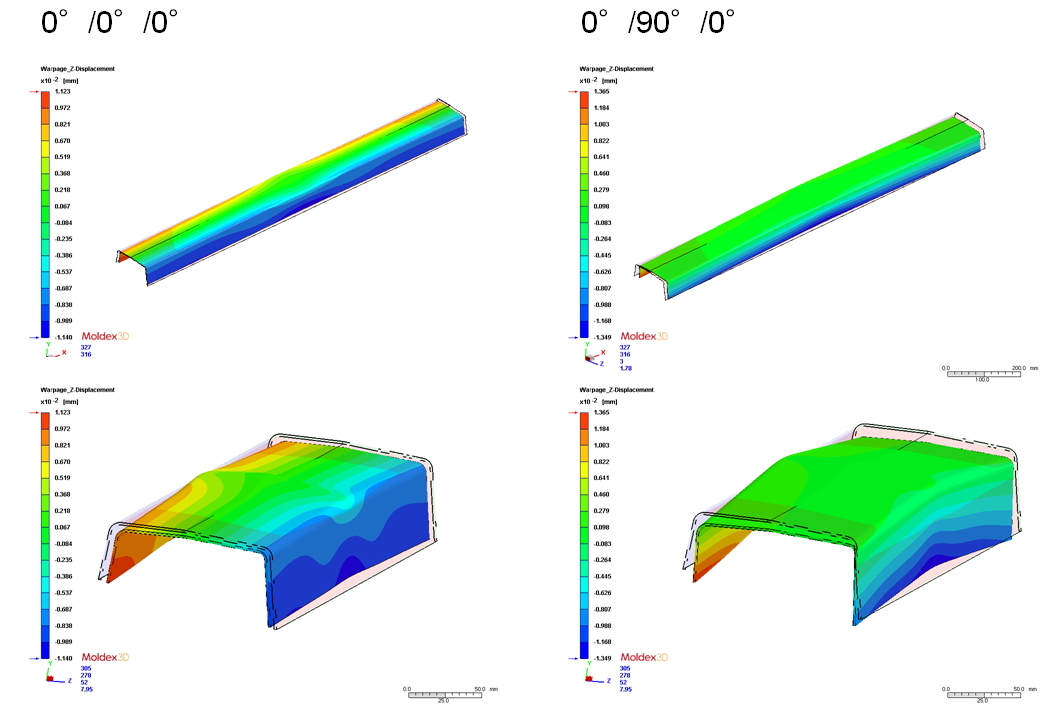

The continuous fiber composite products use anisotropic fiber mats as the reinforced material. However, the anisotropic reinforced material will affect the mechanical strength of the final product.  During the product design stage, the mechanical strength of the part will determine the number and the order of the layers. The draping of different reinforced materials will affect the flow and warpage behaviors during the resin transfer molding (RTM) process. To better evaluate the effect of draping of fiber preforms on part warpage, Moldex3D R16 RTM Analysis supports warpage analysis. Since the anisotropic fiber mat will be used as the reinforced material, we have to set the anisotropic material properties and also the layer orientations according to the layer design during the model preparation. Moldex3D RTM Wizard supports the workflow for assigning the layer orientations and modeling. In addition, the Material Wizard can support the settings for the orthotropic mechanical properties, which will be used for analyzing warpage results. Fig. 1 shows two different layer stacking in the RTM Wizard: 0°/0°/0° and 0°/90°/0°. Fig. 2 shows the mechanical properties settings of plies and resins in the Materials Wizard. Fig. 3 shows the warpage results after the Flow and Warp analysis. Moldex3D R16 RTM Warp supports the modeling of orthotropic materials to predict the effect of draping of fiber preforms in different directions on the warpage results. With Moldex3D, users can better evaluate the manufacturability before production, reducing the number of costly mold trials required to achieve optimal processing conditions. Snow Rolling Brush for Road Clearing,Snow and Debris Roller Brush Cleaner,Pickup Truck Snow Brush Attachment,All-Terrain Snow Brushing Equipment Henan Lukewei Road Machinery Manufacturing Co.,Ltd , https://www.lukeweimachinery.com

Fig. 1 Setting the directions of each layer (ply) in the RTM Wizard

Fig. 2 Setting the mechanical properties the resin and the ply (layer) material

Fig. 3 The warpage analysis results with the consideration of the effect of layers in different directions

Predicting Warpage Behaviors of Different Draping Directions for RTM Products

Our company specializes in the manufacturing and supply of high-quality Snow Removal Equipment, designed to handle the rigors of winter weather with efficiency and reliability. We offer a comprehensive range of products that cater to various snow clearance needs:

1. **China Snow Rolling Brush**: Engineered for durability, our snow rolling brushes are designed to provide efficient snow removal from roads and pavements. They are built with a robust construction to withstand the harsh winter conditions and are easily attachable to a variety of vehicles for versatility .

2. **Snow Roller Brush Equipment**: Our snow roller brushes are known for their large torque and high-speed operation. They are lightweight yet powerful, ensuring that snow is cleared quickly and effectively. These brushes can be installed on various vehicles, including washing cars, sprinkler trucks, hook arm trucks, and compression vehicles .

3. **Pickup Truck Snow Brush**: For those looking for a more mobile solution, our snow brushes are designed to fit pickup trucks. They are easy to install and provide a wide range of snow clearance, ensuring that your truck can handle the snow with ease.

4. **Snow Plow Roll Brush**: Our snow plow roll brushes are designed for heavy-duty use. They are built to last and provide efficient snow clearance even in the most challenging conditions.

We pride ourselves on offering products that are not only low in price but also high in quality. Our commitment to innovation and customer satisfaction means that our products are designed to make snow removal as straightforward as possible, reducing the time and effort required to keep roads and pathways clear and safe this winter.